Real Artisanry: Chop 'til you Drop (5 Min Read)

Posted by Cal Virgilio on Feb 9th 2022

When you search the word "artisan" online, you'll find definitions that include, "worker in a skilled trade especially one that involves making things by hand" or, "person skilled in a utilitarian art, trade, or craft, especially one requiring manual skill." Point being--real artisanry requires being hands-on. A way of work that was once common is now rare in the automation generation. Big business has put efficiency first, quality second, in a race for market share and profit margins.

When you make something by hand, you're much more connected to the process that ultimately leads to its level of quality. Imagine a guitar being assembled on a production line overseas that's 90 percent machine automated, and then packaged and sent to a retailer.

Now picture the creation of the famous Martin Guitar in Nazareth, Pa., meticulously designed and crafted by hand, piece by piece. It's quality and sound are unmatched, in large part due to the artisan process. It's the reason so many great musicians have chosen Martin guitar for over 180 years.

The same goes for companies like Patagonia. While their products aren't as hand-crafted as Martin Guitar, it's their commitment to quality that motivates them to design clothing with a hands-on approach. Their artisan mindset is why their clothes have some of the longest life spans and durability in the industry.

As a small artisan bakery, we strive to emulate companies like Martin Guitar and Patagonia that have grown their scale without compromising their artisan heritage. As we grow, there will be components of our baking processes that we'll have to make more efficient, but we will never sacrifice quality for efficiency. We will never lose sight of being hands-on with our products because it assures quality and consistency. This is our commitment to to real artisanry, and we look forward to sharing how we implement it into our products.

Artisan Granola

It began in my mother’s kitchen 35 years ago. She would make her honey pecan granola one tray at a time and serve it to guests at her bed and breakfast. Her recipe used seven ingredients and a simple hands-on approach to baking. The result was a granola that was crunchy at first but would melt in your mouth. It had a buttery flavor complemented by the pecans and a sweet and salty finish from the clover honey and kosher salt. This was artisan baking at it’s finest.

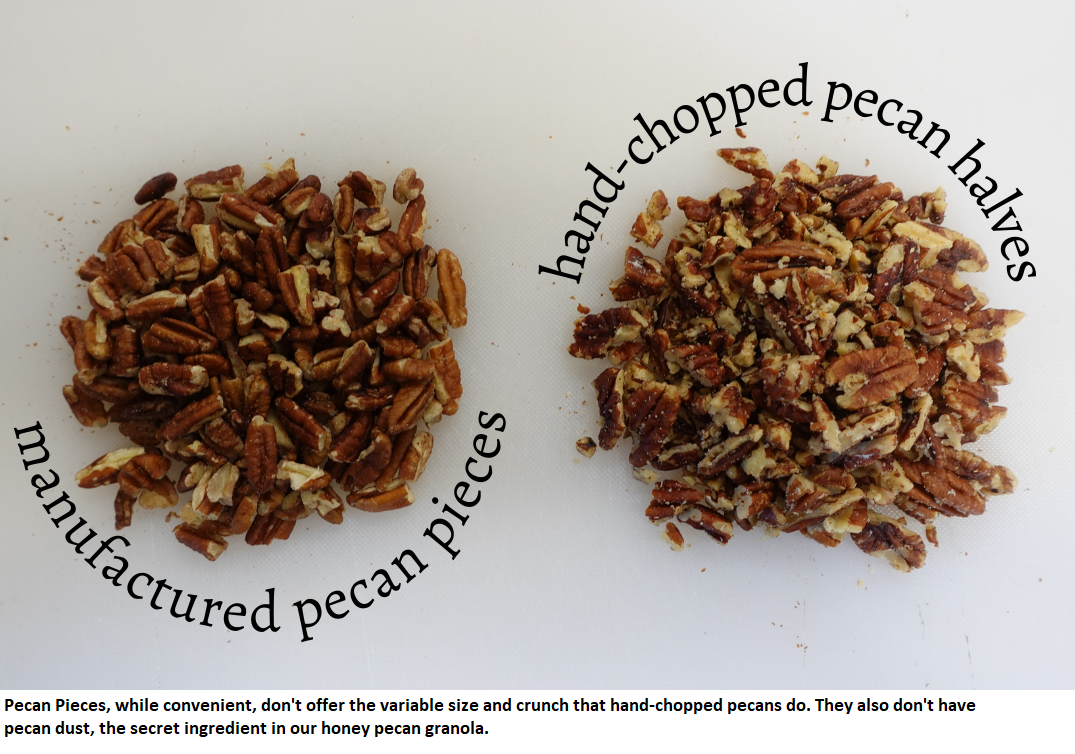

While her method of artisan baking is simple in a small batch, it can be labor intensive when making 1,000s of pounds of granola per week. Imagine scaling from 1 cup to 100 pounds of pecan halves, and chopping them all with a chef’s knife. It wouldn’t be cost effective, but we found that commercially produced pecan pieces are too small and they lack the size and texture of hand-chopping.

The Art of Chopping Pecans

I recently had breakfast with a gentleman who runs a much larger food business than Granola Factory. His company specializes in nuts, dried fruits, and confectionary snacks. In discussing our baking processes with him, I mentioned that we use pecan halves in our honey pecan granola, but that we chop them by hand before adding them to the recipe. He looked at me like I was crazy! “Why not just use pecan pieces?” he said, referring to the fact that we could buy pecans that were already chopped into small pieces by machines. This would be a lower cost ingredient and use less labor in our production process.

On the surface it seems like a no brainer, until you realize how it would impact the quality of our granola. Our honey pecan has a mix of small and large chunks of pecans that require hand-chopping in small quantities. We do this because commercial pecan pieces are consistently too small, and using whole pecan halves are too large. Ratio is important in food and flavor. You want the right mix of oats, honey, butter and pecans in each bite.

There is one more important difference between the two: pecan dust. When you rough chop pecans by hand, it creates pecan dust that becomes a secret ingredient in our granola. The pecan dust disperses more pecan flavor throughout the granola, even when you don’t get a spoonful with a pecan included.

Chopping Pecans with Real Artisanry

Each batch of granola requires us to hand-chop pecans with a small nut-chopper. While we’ve upgraded from our original chef's knife, the hand-chopper keeps it simple and the quality superior. We’ve realized that although it adds time to our process each day, it also adds uniqueness, flavor and texture.

While we’ve found ways to scale our processes as we’ve grown, there are still components that are the same as they were 35 years ago in our home kitchen. We look forward to sharing more examples real artisanry in our products.

Calvin is the son of founders Robert and Suzanne Virgilio, and the director of operations at The Granola Factory.